In the increasingly competitive world of eCommerce and logistics, future-proofing your supply chain and maintaining a healthy inventory turnover are essential. Efficient inventory management prevents waste, maximises stock availability, and ensures you never run out of products at crucial times.

This guide covers the importance of inventory turnover, how to calculate it, and how to use this metric to enhance your supply chain and ensure a seamless and satisfying customer experience.

What is Inventory Turnover?

Inventory turnover measures how many times a company sells and replaces its inventory over a specific period, usually a year. It provides insights into how effectively a business is managing its stock and can indicate the liquidity of the inventory, helping business owners make informed decisions about purchasing, pricing, and production.

Why is Inventory Turnover Important?

Cash Flow Management

High inventory turnover indicates that a company is selling goods quickly, leading to a steady inflow of cash. This is essential for maintaining a healthy cash flow, which is vital for covering operational expenses and investing in growth opportunities.

Storage Costs

Efficient inventory turnover reduces storage costs. Holding excess inventory ties up capital and increases costs related to storage, insurance, and obsolescence.

Product Freshness

For businesses dealing in perishable goods or products with a short shelf life, high inventory turnover ensures that items are sold while they are still fresh and before they become obsolete.

Customer Satisfaction

Maintaining optimal inventory levels helps meet customer demand promptly, leading to higher satisfaction and repeat business.

How to Calculate Inventory Turnover

The inventory turnover ratio is calculated using the following formula:

Inventory Turnover = Cost of Goods Sold (COGS) / Average Inventory

Here’s a step-by-step guide:

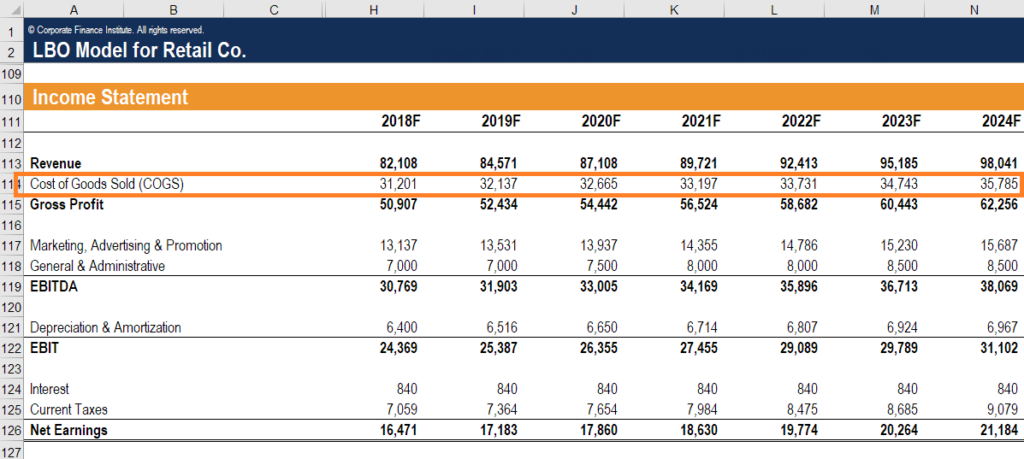

Step 1: Determine the Cost of Goods Sold (COGS)

COGS represents the direct costs attributable to the production of the goods sold by a company. This includes the cost of materials and labour used to create the product. You can find this figure on your income statement. COGS is usually the second line item in your income statement, coming right after your sales revenue:

To find the cost of goods sold, you can use the following formula:

COGS = Starting Inventory + Purchases – Ending Inventory

To implement this effectively, however, you need a clear and consistent method for valuing your inventory and accounting for your costs.

This is where a WMS like Despatch Cloud’s comes in, providing you with an easy and effective way to track your inventory across warehouses, sales channels and marketplaces, so you can always stay on top of your stock. You can then use these insights to inform your calculations and properly assess stock trends.

Step 2: Calculate Average Inventory

Average inventory is calculated by taking the total inventory value at the beginning of a period, add it to the total value at the end, and divide it by two:

Average Inventory = (Beginning Inventory + Ending Inventory) / 2

Step 3: Apply the Formula

Once you have COGS and average inventory, apply the inventory turnover formula:

Inventory Turnover = Cost of Goods Sold (COGS) / Average Inventory

Example Calculation

Let’s assume your business had a COGS of £500,000 for the year. At the beginning of the year, your inventory was valued at £100,000, and at the end of the year, it was valued at £150,000.

First, we need to calculate the average inventory:

Average Inventory = (£100,000 + £150,000) / 2 = £125,000

Once that’s done, we apply our formula:

Inventory Turnover = £500,000 / £125,000 = 4

This means your inventory turned over four times during the year.

Interpreting Inventory Turnover Results

High Turnover Ratio

A high inventory turnover ratio generally indicates strong sales and effective inventory management. However, if the turnover is too high, it might suggest that the business is struggling to keep up with demand, leading to potential stockouts and lost sales.

Low Turnover Ratio

On the other hand, a low inventory turnover ratio can indicate overstocking, obsolescence, or weak sales. This can tie up capital in unsold goods and increase storage costs. It may also suggest that a business needs to improve its marketing or sales strategies.

Strategies to Improve Inventory Turnover

1. Accurate Demand Forecasting

Use historical sales data and market trends to predict future demand accurately. This helps in ordering the right amount of stock and avoiding overstocking or understocking.

2. Efficient Inventory Management Systems

Implementing an inventory management system can significantly improve the efficiency and accuracy of your stock management processes.

By automating stock tracking, it eliminates manual errors and reduces the time spent on inventory counts, ensuring you always have accurate data on hand.

Real-time data provided by these systems allows you to monitor inventory levels instantly, making it easier to identify trends, predict demand, and make informed decisions.

Additionally, an inventory management system helps manage reorder points effectively by setting automatic alerts when stock levels fall below a certain threshold, ensuring you never run out of crucial products and can maintain optimal inventory levels. This proactive approach not only prevents stockouts and overstock situations but also enhances overall operational efficiency and customer satisfaction.

3. Regular Inventory Audits

Conducting regular inventory audits is a vital practice to maintain accurate stock levels and ensure your inventory reflects the actual quantities on hand.

Regular audits help identify discrepancies between recorded inventory and physical stock, allowing you to address issues promptly and maintain data integrity.

These audits also enable you to spot slow-moving or obsolete items that are taking up valuable warehouse space. By identifying these items, you can implement strategies to discount or liquidate them, freeing up resources and capital that can be better utilised elsewhere.

Additionally, regular inventory audits help prevent stockouts of high-demand items, ensuring your inventory is optimised for customer needs and operational efficiency. This proactive approach supports a healthy inventory turnover rate and contributes to a more streamlined, cost-effective supply chain.

4. Optimise Your Product Mix

Optimising your product mix involves analysing sales data to understand which products are performing strongly and which ones are slower moving. By leveraging advanced analytics and sales reports, you can gain insights into customer preferences, seasonal trends, and market demands. This understanding allows you to strategically allocate resources towards stocking popular items that drive revenue and profitability.

For high-performing products, consider increasing stock levels to meet demand and capitalise on sales opportunities. This proactive approach ensures you maintain adequate inventory levels without risking stockouts. Conversely, for slower-moving items, adjusting your purchasing strategy or promotional efforts can help reduce excess inventory and minimise holding costs.

Optimising your product mix also involves making informed decisions about new product introductions or discontinuations based on sales performance and market analysis. By focusing on stocking items with higher turnover rates and phasing out less profitable products, you can streamline your inventory management and enhance overall operational efficiency. This approach not only improves inventory turnover but also aligns your product offerings more closely with customer preferences, thereby enhancing customer satisfaction and loyalty.

5. Supplier Relationships

By fostering close partnerships with suppliers, businesses can negotiate favourable terms, lead times, and prices that align with their inventory needs and financial goals.

Negotiating better terms with suppliers can include securing discounts for bulk orders or establishing favourable payment terms that improve cash flow. These agreements enable businesses to reduce procurement costs and enhance profitability while maintaining consistent stock levels.

Establishing reliable communication channels and fostering trust with suppliers facilitates proactive inventory replenishment. By sharing sales forecasts and demand projections, businesses can ensure timely stock replenishment, minimising stockouts and meeting customer demands effectively.

Moreover, strong supplier relationships enable businesses to navigate supply chain disruptions more effectively. When unforeseen events impact the availability of goods, trusted suppliers are more likely to prioritise fulfilling orders for their dependable partners.

Overall, investing in building and maintaining strong supplier relationships not only optimises inventory management but also enhances operational resilience, cost-efficiency, and customer satisfaction. It establishes a foundation for collaborative growth and long-term success in the competitive marketplace.

Conclusion

Understanding and calculating inventory turnover is vital any business to manage their stock efficiently, optimise cash flow, and maintain customer satisfaction. By regularly monitoring this metric and implementing strategies to improve it, businesses can enhance their overall operational efficiency and drive growth, while controlling costs.

Strategies such as conducting regular inventory audits, optimising your product mix, and nurturing supplier relationships can significantly improve supply-chain health and inventory turnover. Additionally, businesses can leverage inventory management systems to simplify stock management and get comprehensive insights into stock trends and market demand to make more accurate demand predictions and better purchasing decisions.

Looking for a more efficient way to manage your stock?

Check out our stock management solution. From multichannel stock syncing and stock alerts to purchase order suggestions and digital stock counts, we help you simplify your inventory keeping and futureproof your business as you grow.