How to Choose a Warehouse Management System (WMS)

In today’s fast-paced supply chain environment, a WMS plays a crucial role in optimising core warehousing processes and providing real-time visibility into inventory levels and warehouse activities. The automation and data insights offered by a WMS enable businesses to meet customer demands promptly and accurately, minimising errors, reducing operational costs, and improving overall efficiency. Selecting the right WMS for your business is essential because it directly impacts the quality of your operations. A good WMS match is one that addresses your pain points in the most efficient and cost-efficient way, supports your integration requirements and is compatible with your operational structure, streamlining processes and reducing manual labour. On the other hand, an ill-fitting WMS can cause disruptions, inefficiencies, and increased operational costs.Assessing Your Warehouse Needs

Before start looking at WMS providers is crucial that you evaluate your current operations, identify pain points and inefficacies and determine key requirements. These can be:

💡 Scalability

As your business grows, your warehouse operations will need to expand accordingly. A scalable WMS can adapt to increased inventory, more complex order processing, and additional warehouse locations without requiring significant overhauls or replacements. Scalability ensures that your system can handle peak seasons, market expansions, and new product lines seamlessly. When evaluating a WMS, consider its ability to support growth without compromising performance.

💡 Integration capabilities

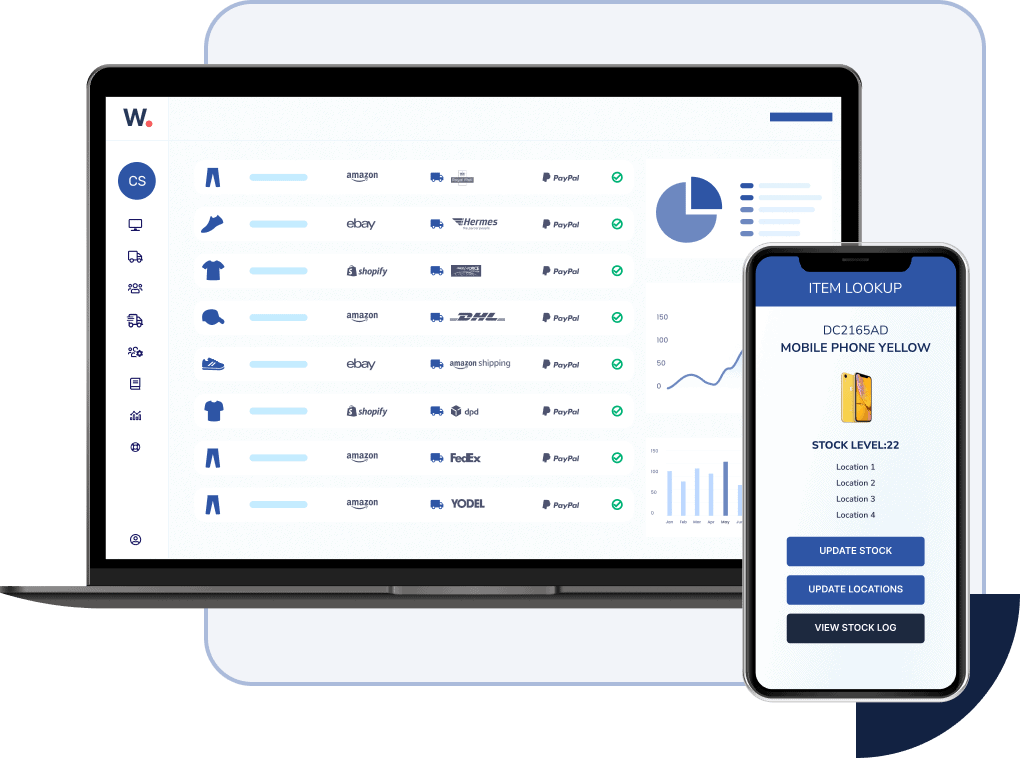

In today’s interconnected business environment, seamless integration with other systems is vital. Your WMS should be able to connect with various platforms such as ERP (Enterprise Resource Planning) systems, eCommerce platforms, and courier services. This integration allows for real-time data exchange, which is essential for maintaining accurate inventory levels, streamlining order processing, and ensuring efficient shipping. A WMS with robust integration capabilities reduces manual data entry and errors, enhancing overall operational efficiency.

💡 User-friendliness

The usability of a WMS is a critical factor for its successful implementation and daily use. A user-friendly system should have an intuitive interface that requires minimal training for your staff. This ensures that your team can quickly adapt to the new system, leading to fewer errors and increased productivity. Look for features such as customisable dashboards, easy navigation, and clear instructions that can help users perform their tasks efficiently.

💡 Specific industry needs

Different industries have unique requirements that a WMS must address. For instance, a WMS for a food distribution business must handle expiration dates and batch tracking, while a pharmaceutical company might need stringent compliance and traceability features. Identifying your industry’s specific needs ensures that the WMS you choose can support specialised processes, regulatory requirements, and industry best practices. A tailored WMS can provide functionalities that cater specifically to your business model, enhancing operational effectiveness.

By thoroughly assessing these key requirements, you can better understand what to look for in a WMS and ensure that the system you choose will effectively meet your operational needs and support your business growth.

Features to Look for in a WMS

When selecting a Warehouse Management System (WMS), certain features are essential to ensure smooth and efficient warehouse operations. Below are key features to look for in a WMS:

💡 Inventory Management

Real-Time Tracking: A WMS with real-time tracking capabilities allows you to easily monitor inventory levels and locations. This ensures accurate stock counts and helps prevent stockouts or overstock situations.

Stock Level Optimisation: Effective stock level optimisation ensures that you always have the right amount of stock, reducing holding costs and maximising availability. This includes features such as demand forecasting, reorder point calculation, as well as purchase order suggestions and stock alerts.

Read more on our top tips for eCommerce inventory management here.

💡 Order Fulfilment

Picking and Packing Efficiency: A robust WMS should streamline the picking and packing processes. Features like optimised pick paths, batch picking, and packing instructions can significantly enhance efficiency and accuracy, reducing order fulfilment times.

Shipping Integrations: Seamless integration with shipping carriers is crucial for efficient order dispatch. A WMS should support multiple shipping options and provide automatic label generation, tracking, and carrier selection based on predefined criteria.

💡 Automation and Robotics

Compatibility with Automated Systems: As warehouses increasingly adopt automation, it’s vital that your WMS can integrate with automated systems such as conveyor belts, robotic pickers, and automated guided vehicles (AGVs). This compatibility enhances efficiency and reduces labour costs.

💡 Analytics and Reporting

Data-Driven Decision-Making Tools: Analytics and reporting features allow you to make informed decisions based on real-time data. A good WMS should offer customisable reports on key performance indicators (KPIs) such as order accuracy, picking efficiency, and inventory turnover, helping you identify trends and areas for improvement.

💡 Integration Capabilities

ERP Systems: Integration with ERP systems ensures a seamless flow of information across your entire business. This integration allows for better coordination between departments and more accurate financial and operational planning.

eCommerce Platforms: Connecting your WMS with eCommerce platforms like Shopify, Amazon, and eBay helps synchronise inventory levels, process orders, and manage returns effectively.

Courier Services: Direct integration with courier services simplifies the shipping process. This feature allows for automated shipping rate calculations, real-time tracking, and streamlined communication with carriers.

💡 Scalability and Flexibility

Support for Multi-Location Operations: If your business operates multiple warehouses or plans to expand, a scalable WMS should support multi-location operations. This feature enables centralised management and visibility across all locations.

Adaptability to Business Growth: As your business grows, your WMS should be able to adapt to new requirements, increased transaction volumes, and additional product lines. Look for a system that can scale with your business without requiring significant reconfiguration or replacement.

By focusing on these critical features, you can select a WMS that enhances operational efficiency, reduces costs, and supports your business’s growth and adaptability.

Vendor Evaluation Criteria

Choosing the right WMS vendor is as crucial as selecting the system itself. Here are key criteria to consider:

💡 Reputation and Experience

Customer Reviews and Case Studies: Look for vendors with positive feedback from similar businesses. Case studies can provide insights into how the WMS has been successfully implemented and its impact on operations.

Industry Expertise: Ensure the vendor has experience in your industry, which can be crucial for understanding specific needs and challenges.

💡 Support and Training

Onboarding Process: Evaluate the vendor’s process for getting your team up and running. Comprehensive training and a clear implementation plan are essential.

Ongoing Support: Reliable, ongoing technical support is crucial. Check if the vendor offers 24/7 support, dedicated account managers, and resources like help centres or user communities.

💡 Cost and ROI

Pricing Models: Understand the vendor’s pricing structure, including any setup fees, subscription costs, and additional charges for support or updates.

Potential Return on Investment: Assess the long-term value the WMS can bring, such as efficiency gains, reduced errors, and scalability, to determine the potential ROI.

💡 Customisation and Configuration

Tailoring the System: Determine the extent to which the WMS can be customised to fit your specific business needs. The ability to configure workflows, reports, and integrations is important for seamless operations.

Scalability: Ensure the system can grow with your business, accommodating increased volumes and additional functionalities as needed.

Implementation Considerations

Implementing a Warehouse Management System (WMS) requires careful planning and execution to ensure a smooth transition and effective utilization. Here are key considerations:

💡 Implementation Timeline

Typical Duration and Phases: Understand the timeline for implementation, including phases such as planning, configuration, testing, and go-live. This helps in setting realistic expectations and managing stakeholders.

Project Management: Assign a dedicated project manager to oversee the implementation process and coordinate with the WMS vendor and internal teams.

💡 Change Management

Preparing Your Team: Ensure your team is prepared for the changes brought by the new WMS. This includes training sessions, workshops, and clear communication about the benefits and expected outcomes.

Managing Resistance: Address any resistance to change by highlighting the advantages of the new system and involving key stakeholders early in the process.

💡 Testing and Go-Live

Testing Phase: Conduct thorough testing of the WMS to identify and resolve any issues before the system goes live. This includes testing functionalities, integrations, and performance under various scenarios.

Pilot Phase: Consider running a pilot phase with a smaller scope to validate the system’s effectiveness and gather feedback from users.

💡 Ensuring Smooth Operation from Day One

Support and Training: Provide ongoing support and training to users post-implementation to ensure they are comfortable with the new system. Address any initial challenges promptly to minimise disruption to operations.

Post-Implementation Review

Once your Warehouse Management System (WMS) is implemented, it’s crucial to conduct a thorough review to monitor performance and ensure ongoing optimisation. Here’s how to approach the post-implementation review:

💡 Performance Monitoring

Key Metrics to Track: Define key performance indicators (KPIs) aligned with your warehouse goals, such as order fulfilment accuracy, inventory turnover, and picking efficiency.

Data Analysis: Utilise the WMS analytics and reporting tools to gather data and generate insights into warehouse operations. Regularly review these metrics to identify trends and areas for improvement.

💡 Continuous Improvement

Adapting and Optimising: Use insights from performance monitoring to make informed decisions about optimising warehouse processes. This may include refining workflows, adjusting inventory strategies, or fine-tuning system configurations.

Feedback Loop: Encourage feedback from warehouse staff and stakeholders on their experiences with the WMS. Incorporate this feedback into continuous improvement efforts to address operational challenges and enhance system usability.

Conclusion

Selecting the right Warehouse Management System (WMS) is a critical decision for any business looking to optimise its supply chain operations.

By thoroughly assessing your current needs and considering key features such as scalability, integration capabilities, and user-friendliness, you can ensure the chosen WMS aligns with your operational goals.

Remember, the right WMS not only enhances efficiency and cost-effectiveness but also improves customer satisfaction through streamlined order fulfilment and inventory management.

Take the time to evaluate your options carefully to make an informed decision that supports long-term success in warehouse management.

Explore Our WMS Solution

Ready to optimise your warehouse operations? Discover how our advanced WMS can streamline your processes, enhance efficiency, and support your business growth.